Today’s automotive maintenance may heavily involve electronics, but mechanical parts replacement remains a vital aspect of the business. When it comes to dealing with hubs, specialized tools like hub extractors come to the rescue. In this comprehensive guide, we’ll focus on hub extractors and how they can significantly ease your job.

Understanding Hubs and Their Significance

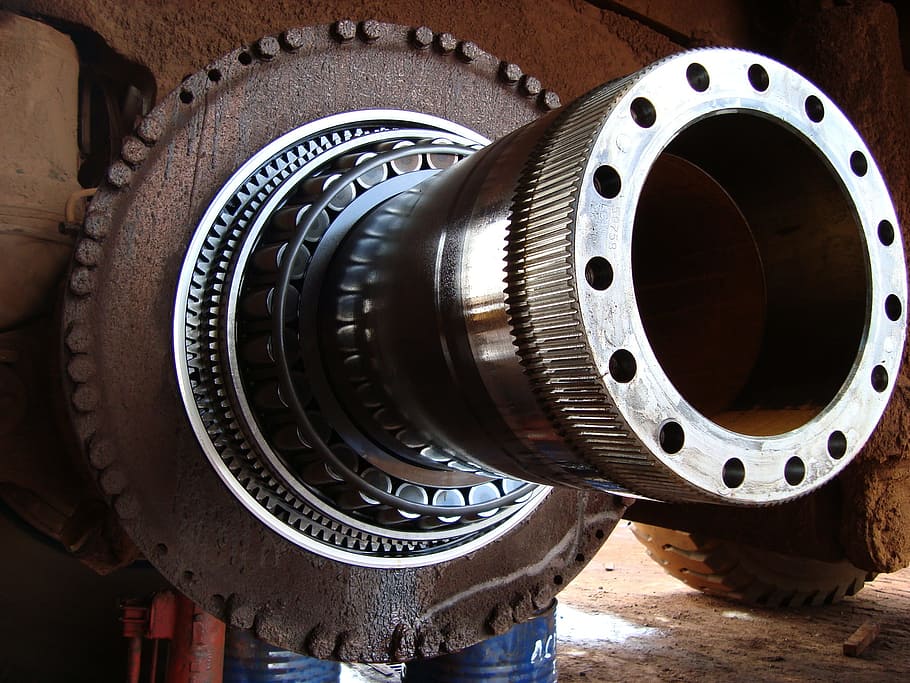

In a car, the hub serves as the rotating component to which the wheel attaches. With both front and rear hubs, each having its specific configuration, removing them becomes challenging due to their mounting on the bearings enabling rotation. Here’s where the hub extractor proves its worth.

Different Types of Hub Extractors

Hub pullers come in various configurations, each offering its own set of advantages and disadvantages. The three main types are universal pullers, flanged hub pullers, and inertia extractors.

Universal Puller: Featuring a large central screw and articulated arms, this extractor’s versatility comes with a caveat—it may not always grip the hub firmly, leading to slippage or deformation. While it can be used for a wide range of hubs, certain models with unconventional shapes may pose difficulties for the universal puller.

Flanged Hub Puller: This specific hub extractor utilizes a central screw screwed into a circular flange, ensuring an easy fit into various wheel screw locations and providing a secure extraction process. The flanged hub puller is ideal for hubs that have standardized flanges, making the extraction process more efficient and reliable.

Inertia Extractor: Replacing the central screw with a metal rod and a cylindrical metal mass, this extractor relies on the inertia effect to tear the hub from the bearings. Its adaptability to all hubs makes it particularly effective when there’s no transmission or hollow stub axle to press against. The inertia extractor’s unique design allows it to handle challenging extraction tasks with ease.

Practical Tips for Hub Extraction

Installing a hub puller is generally straightforward, but the device’s weight (5 to 10 kg) should be considered. Here are some useful recommendations for hub removal:

- Lift the vehicle safely on a flat, hard surface with a jack to avoid unbalancing it during extraction. Safety should always be a top priority when working with heavy tools and automotive components.

- When extracting a hub-drum assembly, disarm the automatic brake adjustment system to prevent the brake shoes from coming off when the drum is removed. This can often be done with a screwdriver. Properly disarming the brake system ensures a smooth and hassle-free hub removal process.

Choosing the Right Hub Extractor

Whether you’re a seasoned do-it-yourselfer or a professional, selecting the appropriate hub puller is crucial for seamless extraction. If you’re a DIY enthusiast and feel confident in using a hub puller, you can opt for affordable consumer sets of inertia hub pullers starting from $90. However, for professional use, investing in a piece of sturdy Premium brand equipment priced between $300 and $700 is recommended for enhanced durability and performance. High-quality tools not only deliver better results but also offer long-term reliability, making them a valuable addition to any automotive repair toolkit.

By gaining a comprehensive understanding of the different types of hub extractors and following practical tips for their application, you can elevate the efficiency and effectiveness of your automotive repair tasks. Whether you’re working on a personal project or handling professional assignments, having a reliable hub puller in your toolkit will ensure smoother and easier hub removal, ultimately saving you valuable time and effort in the process. With this guide at your disposal, transforming your automotive maintenance experience is just a hub extractor away!