Contents

– Centrifugal clutch: how it works

– Centrifugal clutch: advantages and disadvantages

The centrifugal clutch has been abandoned in the automotive industry for a long time, but its simplicity of application still deserves attention, mainly in the vintage car segment. Follow us; we will tell you everything!

Centrifugal clutch: how it works

The operating principle of the centrifugal clutch is based on centrifugal force: when you turn on a rotating ride, the higher the speed, the more the centrifugal force tends to eject you outwards.

The same principle applies to the centrifugal clutch:

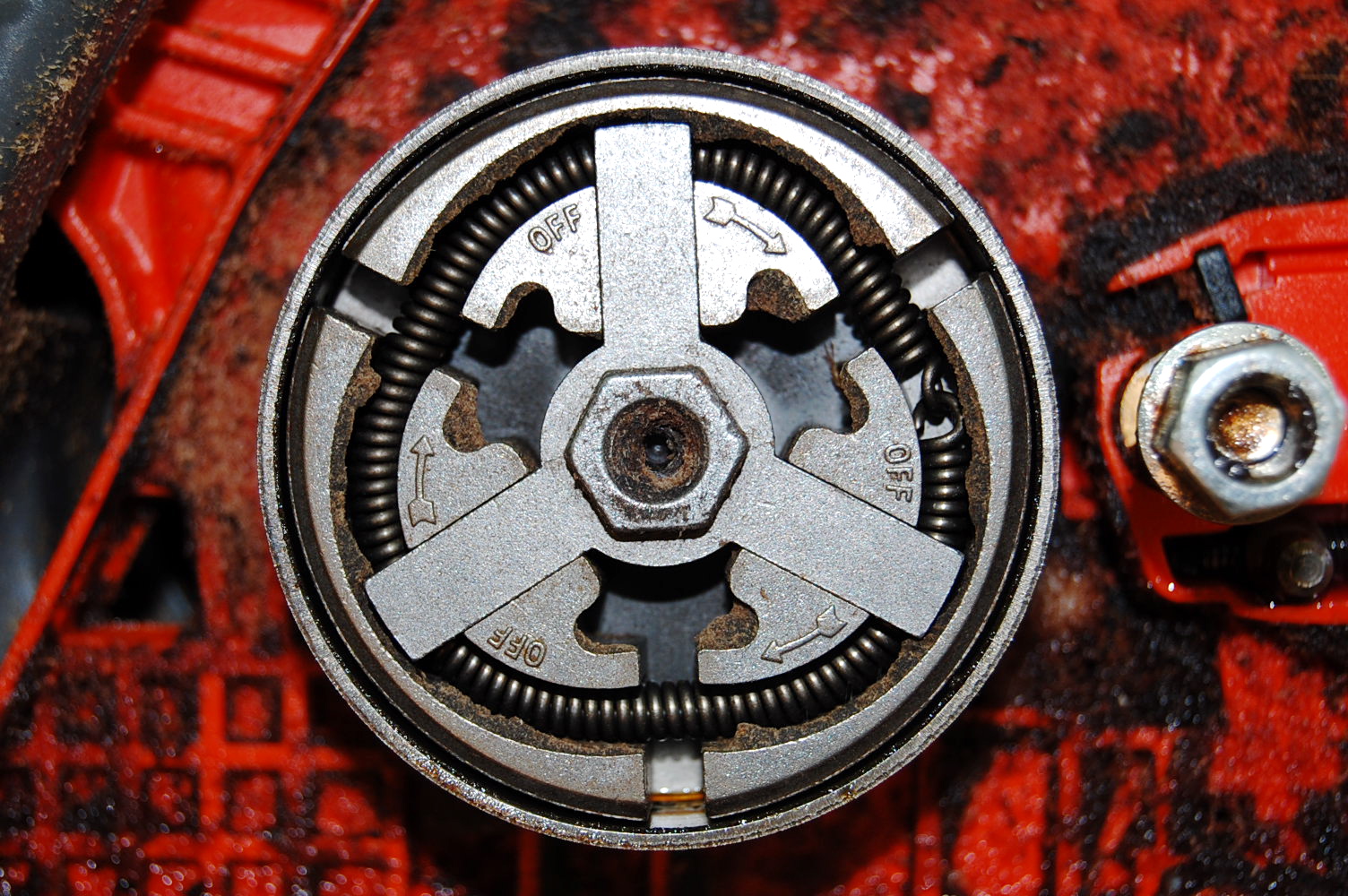

– Hinged centrifugal weights, connected by return springs, integral to the drive shaft, are gradually driven into rotation. The higher the speed, the more they are drawn outwards;

– Their outer part is covered with friction lining. When the travel is sufficiently large, they come to rest against a drum attached to the gearbox;

– The centrifugal force is sufficiently strong to fix them to the drum and thus transmit the engine rotation movement to the gearbox.

Note: in cars, the main known application is the “two horsepower”, well known by collectors. This technology can be found on mopeds, motorcycles, go-karts, and chainsaw or brushcutter engines.

Centrifugal clutch: advantages and disadvantages

The centrifugal clutch has completely disappeared from automotive systems. Let’s look at the advantages and disadvantages of the centrifugal clutch as applied to the “two horsepower”.

Advantages of the centrifugal clutch

The main ones are:

– Simplicity of manufacture: the system does not require technical complexity. The only maintenance required is to check and replace the linings;

– Simplicity of operation: at a certain speed, the system automatically starts working without the driver’s intervention. In the same way, for decelerations, under a determined engine speed, the vehicle disengages itself before the engine stalls. This is especially useful when it is impossible to stall when starting on hills and in traffic jams.

Despite these advantages, this system has not lasted over time.

Disadvantages of the centrifugal clutch

There are some disadvantages:

If the selected speed is too high during deceleration, the engine speed can drop below the clutch value. The vehicle then freewheels, which can be pretty destabilizing;

– When parking on a slope, there is no point in leaving a gear engaged. Only the application of the hand brake will immobilize the vehicle;

– Starting the vehicle with the stroller is impossible, as the engine cannot rotate fast enough;

– This system is not suitable for transmitting the torque and power of modern engines;

– The carburetor must be adapted for a precise idling speed.

Good to know: in the context of a 2 HP centrifugal clutch reconditioning, the cost of the parts of a centrifugal clutch is about $100 in specialized stores.

Read more:

– When Can a Leak Detector Be Used on a Head Gasket?

– How to Change Your Brake Fluid

– How to Verify Braking Noises

– How Do You Restore Car Leather

– Are Puncture Proof Tires Any Good?

– How to Repair a Crack on a Dashboard

– 5 Common Causes of Hydraulic Power Steering Failure

– How to Solve a Power Steering Problem

– 5 Steps to Install a Car Window Film

– Is It Worth Buying an Auto Diagnostic Kit

– Automotive Equipment: What Is the Wheel Balancer Used For

– Ever Wonder If Your Vehicle Has a Misalignment Issue?

– The Solution to Combat Engine Fouling

– Why Will You Remove the Catalyst Converter?

– A Guide to Understanding Automotive Mechanics

– Why Perform a Car Diagnostic?

– Increasing the Turbo Pressure

– What Is Ultrasonic Car Injector Cleaning?

– 4 Essential Tips to Clean a Car Injector