Contents

– Sandwich panel: installation

– Sandwich panel: practical advice

– Cost of installing a sandwich plate

The sandwich plate is a housing with a metal interface (steel or aluminum alloy) placed between the engine block and the oil filter. It is screwed onto the block, and the oil filter is in turn screwed onto this housing. It can be mounted as original or added, its function varying according to these criteria. This post tells you about it right away!

Sandwich plate: installation

The original installation of the sandwich plate

It is mostly found mounted on vehicles of the previous generation (from 1980 to the end of the 90s).

It is usually a steel housing between the oil filter and the engine block. Its particularity is that two hoses connect it to the cooling circuit, thus causing the circulation of the heat transfer fluid, allowing the movement of calories from a hot point to a temperature exchanger) in this housing.

In this case, its main function is a temperature exchange between the oil (about 130°C) and the cooling liquid (about 100°C); its role is therefore to lower the oil temperature (the two liquids are not in direct contact and the temperature exchange is done through the walls of the housing).

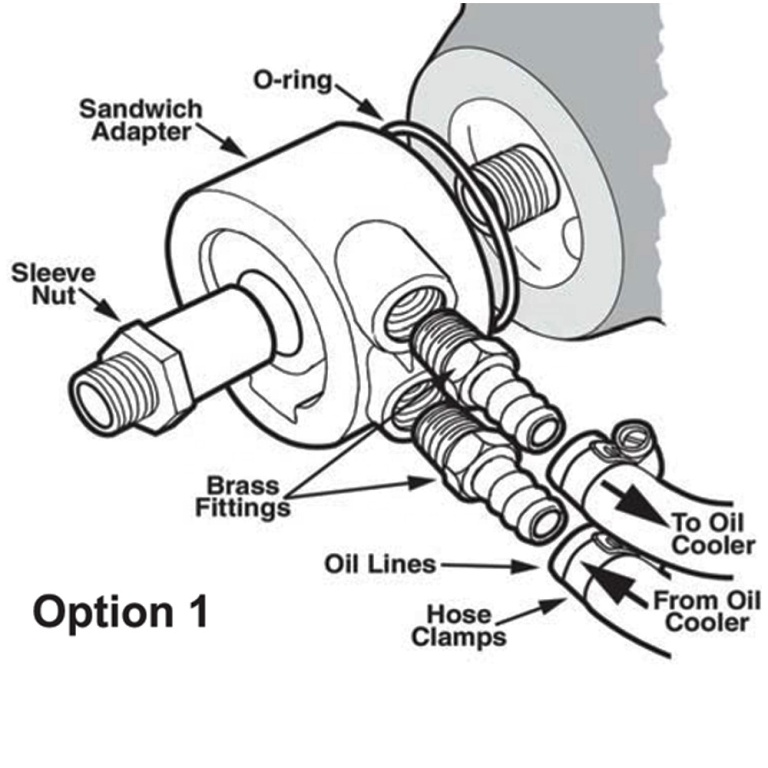

The adaptable sandwich plate

This option has a very different function. While the location and mounting are the same, the function is quite different:

– In this configuration, the housing is installed exclusively on the pressurized oil circuit and thus contains only engine oil;

– Two holes are threaded into the housing body, which is used to accommodate an oil pressure switch and an oil temperature sensor;

– Indeed, often, vehicles do not give the oil temperature information and only have a warning light for the oil pressure, not informing on the value of this one.

These additional devices are therefore appreciated by drivers who want to control and know in real-time all the engine parameters of the vehicle (enthusiasts, tuning, competition drivers…) or simply for image and aesthetics of the vehicle’s interior (many dials on the instrument cluster appreciated by the same tuning enthusiasts…).

Sandwich plate: practical advice

We advise you to proceed to these few checks before using a sandwich plate:

1. seal the sensor threads with Teflon tape or plumbing sealant;

2. coat the sandwich plate seals with a thin layer of engine oil;

3. tighten to the prescribed torque;

4. make a blank assembly of the position of the dials on the dashboard (the location must be prudent, as the installation often requires cutting the dashboard for integration).

Cost of the installation of a sandwich plate

The installation of a sandwich plate can easily be done by yourself; the purchase of the sensor is at a modest cost: an average cost of $35. To this, we must add the price of the temperature sensor, the oil pressure sensor, and their receivers (dials).

The average price of these types of equipment:

– Oil temperature sensor: $30;

– Oil pressure sensor: $45 to $100;

– Oil temperature gauge: $100 to $200;

– Oil pressure gauge: $50 to $100.

Note: the quality of the parts is important! Any oil leak can damage the engine.

Read more:

– The Solution to Combat Engine Fouling

– Why Will You Remove the Catalyst Converter?

– A Guide to Understanding Automotive Mechanics

– Why Perform a Car Diagnostic?

– Increasing the Pressure of a Turbo (Part 1)

– What Is Ultrasonic Car Injector Cleaning?

– 4 Essential Tips to Clean a Car Injector