Contents

– Principle of mechanical injection

– Advantages and disadvantages of mechanical injection

If you have never heard of mechanical injection, it is far from being a new technology. This equipment disappeared at the end of the 1970s for petrol cars and at the beginning of the 2000s for diesel cars on new vehicles. Let’s take a look back and zoom in on this fuel system.

Principle of mechanical injection

The mechanical injection was developed for gasoline and diesel engines, the operating principles of the two engines being different.

Gasoline mechanical injection

This is an injection system installed in the 1950s on production cars by Peugeot and Mercedes in particular. This injection, named Kugelfisher, is undoubtedly the most famous; it was a precision mechanism worthy of a watchmaking system! It was very reliable and well adjusted.

The principle of operation of the mechanical gasoline injection is as follows:

– an electric petrol pump sends the petrol under pressure (1 bar), which is also the injection pressure, to the injection pump itself;

– it contains a camshaft that allows the synchronized distribution of fuel to each cylinder;

– a regulator is also installed to modulate the injection time according to the needs.

The regulator: this is a mechanical part with a variable shape covered by a sensor. Depending on its location on this part (nicknamed “potato” for its particular form), which corresponds to a precise parameter, this sensor modifies the movement on the camshaft of the tappets that control the sending of fuel to the injectors, thus modulating the injection time.

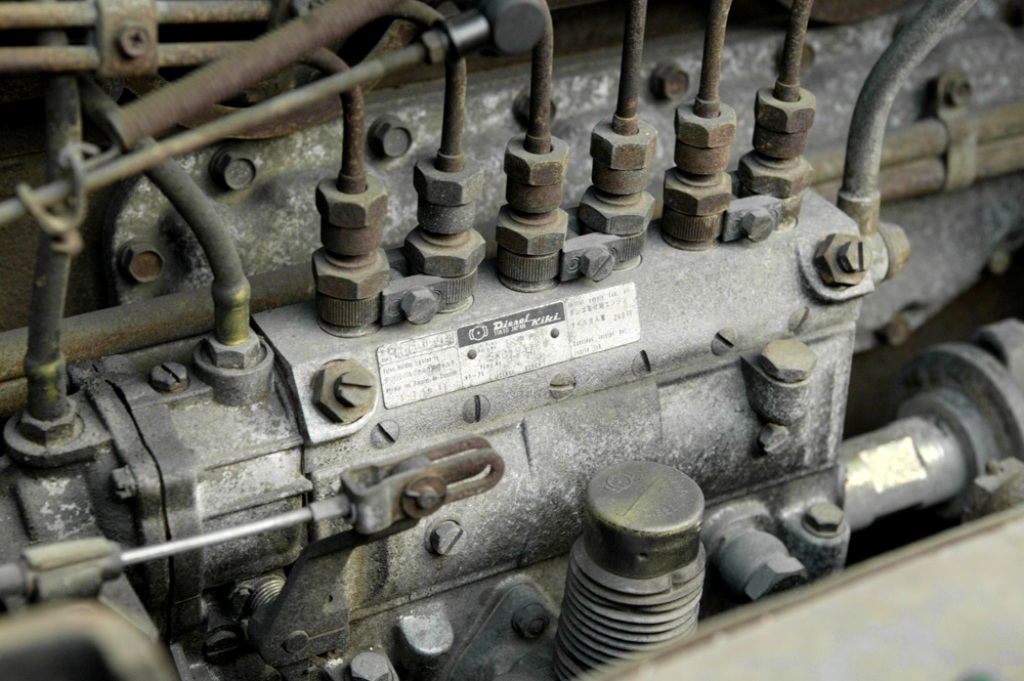

Mechanical diesel injection

Although it has been replaced by “common rail” direct injection, this type of injection still equips many vehicles in the European fleet (production stopped in 2002).

The operating principle of mechanical diesel injection is as follows

– a rotary distributor pump, driven and synchronized by the engine timing system, has several functions;

– It brings the fuel from the tank by an integrated auxiliary pump called the transfer pump;

– it sends the diesel fuel under pressure to the injectors (setting pressure of the injectors: 110 to 175 bars);

– a regulator incorporated into the pump modulates the quantity of diesel injected according to the engine parameters (rotation speed, engine load, etc.).

Advantages and disadvantages of mechanical injection

Mechanical injection for gasoline and diesel has had the same advantages and disadvantages.

Strengths of mechanical injection

– Their characteristic was the absence of electrical and electronic elements, thus considerably simplifying maintenance for mechanics reluctant to use new technologies.

– Reliability was also an important feature, especially for the well-proven diesel systems.

Weaknesses of mechanical injection

– If maintenance was simple, the maintenance periodicity of the injection was short (every 20 to 40,000 km), compared to current cars where the maintenance of the system is theoretically reduced to zero.

– Consumption was higher than today’s systems (20 to 30 % for petrol mechanical injection and 10 to 20 % for diesel-mechanical injection).

– The major issue concerns polluting emissions, which are far too high compared to current standards, especially for mechanical gasoline injection, especially for its CO (carbon monoxide) emissions: 2 to 4% (correct setting), compared to 0% tolerated on current injections.

To conclude: it seems illusory today for lovers of this type of technology to see it implemented on a vehicle, if not on a collector’s car.

Read more:

- Cars and Motors Topics | What is Common Rail Direct Injection;

- 1930-1992 Car Nostalgia: Do You Remember the Indirect Injection?

Did you like this post? Remember to share your views in the comments below.