Contents

– What is torque?

– Wheel torque: proper mounting

Mounting a wheel on a car is a common operation but essential for the safety of the passengers. For the assembly to be done correctly, you must screw in each bolt with a specific torque.

What is torque?

Torque is used when you must tighten a bolt with a tool.

Bolt connections

A bolt connection consists of assembling two parts (for example, a car wheel on its hub) in such a way as to make them immobile, using one or more bolts. You can disassemble the assembly.

The bolt can be a screw or a stud connected to a nut.

Principle of the bolt connection

The assembly of two parts by the bolt is based on applying a force that brings the two parts together. This force, in turn, creates frictional forces between the elements that hold them together.

Good to know: a bolt joins two parts together by the principle of adhesion, creating a force that pulls the two parts together. A bolt is not designed to act as a barrier between the two elements to keep them immobile.

The force created by the bolt between the two parts is reflected oppositely by a tension force in the bolt.

Tightening Torque

The tension force applied in the bolt is directly related to the torque applied to the nut.

Torque is a rotational force applied to an axis and is expressed in Newton meters (N.m).

Good to know: to get an idea of this unit of measurement, a torque of 10 N.m is approximately equivalent to a rotational force resulting from a weight of 1 kg applied to a lever arm of 1 meter.

The relationship between the tension force in the bolt depends on many parameters:

– the diameter of the bolt or stud;

– the diameter of the nut;

– the coefficient of friction at the thread;

– the coefficient of friction at the nut;

– the pitch of the screw or stud.

In summary, the torque is determined by the bolt’s size and the materials of the parts being joined.

Wheel torque: proper assembly

A car wheel consists of a hub attached to the suspension and a removable rim that holds the tire.

Different types of wheels

The wheel hub is usually made of steel, but the rim can be made of several materials:

– sheet steel rims: inexpensive but quite heavy;

– aluminum alloy rims: lighter, more aesthetic, but also more expensive;

– Magnesium alloy wheels: even lighter but very expensive, and therefore reserved for exotic cars.

On the other hand, the rim can be made integral with the hub by several assemblies:

– 4 bolts or 5 bolts.

– A single bolt consists of a hub with a large diameter central axle associated with a nut of the same diameter. Within this central pin and nut configuration, there are 2 possibilities:

◦ the central axis and the rim are equipped with splines that prevent rotation between the two parts: the central nut is only used to avoid the wheel from coming out by itself ;

◦ the central axis is smooth: the central nut then serves to prevent the wheel’s rotation on the hub thanks to the principle of assembly by adhesion.

Proper tightening torque

Depending on the rim material and the type of fastener, the mounting of a wheel involves different tightening torques to be applied to the nuts.

Tip: Refer to the car manufacturer’s service manual to determine what torque to apply to the nuts.

However, as an indication, you can have an idea of the torque to apply to a nut according to the bolt’s diameter.

Here are the correspondences for the most common bolt sizes used on a steel rim:

– 10 mm diameter bolt: approximately 60 N.m ;

– 12 mm diameter bolt: about 80 N.m;

– 14 mm diameter bolt: about 110 N.m.

Good to know: for an aluminum alloy rim, apply a torque approximately 20% higher.

The case of the central axle and nut assemblies is different, and it is necessary to refer to the manufacturer’s instructions:

– if the axle is equipped with splines, the torque to be applied can be around 150 N.m;

– if the axle is smooth, the tightening torque must be higher and go up to 500 N.m.

How do you mount a wheel yourself?

To apply the proper torque to the nuts, you need to be equipped with a measuring tool.

The torque wrench allows you to tighten a nut by indicating the desired torque. When the desired torque is reached, a click informs the user that it is useless to continue tightening.

Good to know: a torque wrench is associated with a specific torque range. For example, a torque wrench can operate between 30 N.m and 200 N.m. Before purchasing a torque wrench, you should check that the torque values to be respected are indeed contained within the wrench’s operating range.

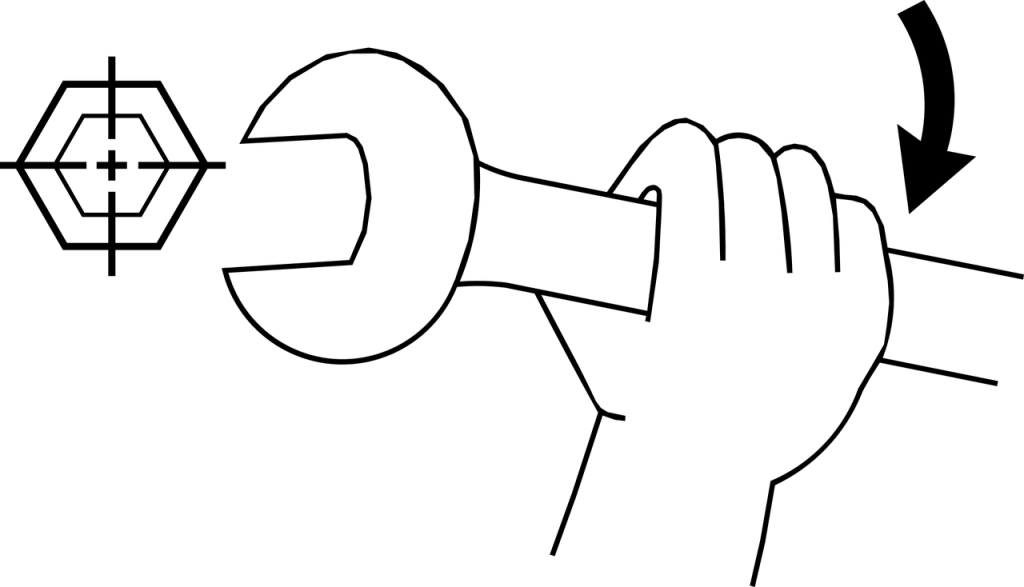

For wheels assembled with 4 or 5 bolts, it is necessary to respect a “cross” tightening order (i.e., tighten alternately opposite bolts to the center of the wheel) to distribute the mechanical stresses better.