Brake discs are the large metal discs visible behind the wheels of a car. They rotate with the wheels so that they stop the vehicle when the brake pads tighten on them. Brake discs have to withstand an enormous amount of heat. Not only that, they have to dissipate this heat into the air as quickly as possible because the brakes will probably be reapplied in a short time. If the surface of the disc becomes uneven over time, braking becomes nervous and less effective. This is usually called deformation.

How brake rotors deform

A common misconception when rotors are called “deformed” is that they are no longer straight when rotating (similar to the way a bicycle wheel deforms). For this to be the case for cars, the rotors themselves would have to be defective because the temperature required to make the metal elastic enough to bend would be enormous.

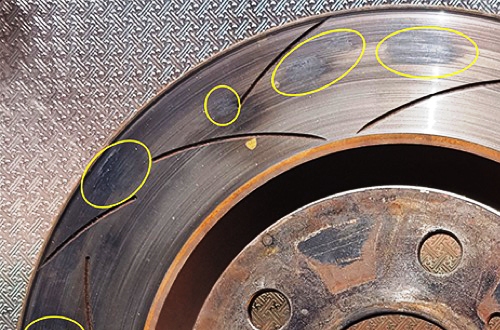

Instead, warping refers to the flat surface of the rotor becoming uneven. Heat is the number one cause and can distort in many ways:

Polishing of the brake rotor with the brake pad material.

This happens because brake pads, like tires, are made with different hardness and stickiness depending on the intended purpose. When the brake pads are too hot for driving and braking at high speeds, or if they brake for an extended period, the adherent material may become too soft and “paint” the brake discs. This means that the brake pads will not cling to the metal when the brakes are reapplied, resulting in a decrease in braking performance that is not as smooth as before.

Wear on the rotor surface and make harder stains in the metal remain slightly lifted from the surface.

The reason why the brakes don’t wear out much revolves around a relatively simple concept. Because the rotor’s metal is more rigid than the brake pad by applying friction to it, the bearing wears while the rotor remains mostly unchanged. With excessive heat, the metal becomes soft enough that the pad wears on the rotor surface. This means that slightly less dense spots in the metal wear more quickly and bring out the harder spots, causing warping.

How to prevent warped brake rotors

To prevent the brake rotors from becoming enameled with the brake pads, consider the vehicle’s braking level to what is done in regular operation. When descending slopes for extended periods, control vehicle speed by shifting the transmission into a lower gear. For automatic systems, the only option is usually to shift to “3”, while vehicles equipped with manual or other transmissions may choose the best gear based on engine speed. When the brakes are hot, never sit with the brake pedal in one place.

Also, when brake pads are first installed, they should be appropriately ground to ensure that they do not leave too much material on the brake disc. This usually involves bringing the car up to road speed and then braking until it slows down to 10 miles per hour. After this is done several times, you can make your way to braking to a complete stop. This allows the brake pad to work better during hard braking further down the road.

The steps that can be taken to avoid excessive wear on the brake rotor surface are similar to the above measures to prevent warped rotors. Be sure to avoid hard braking when the brake rotors have become hot after prolonged use.

What do deformed rotors look like?

There are a few symptoms to look for when diagnosing deformed rotors:

If the brake discs are icy, you may hear excessive squealing when the brakes are applied or even a burning rubber smell.

If braking becomes sudden and uneven, the brake discs should be the first suspect.

If the vehicle vibrates when stationary, the brake rotor is probably deformed, and you should preferably take it to a professional mechanic.