Repairing a gearbox is a high-tech operation using specific tools and is therefore reserved for experienced specialists.

However, in 2 cases that can be identified by specific symptoms, you can intervene by yourself and avoid significant costs. We will go through this part further below.

Equipment needed to successfully repair a gearbox:

1. Gearbox puller

2. Chiffon

3. Socket wrench

4. Torque wrench

5. Flat spanner

6. Carjack

7. Tire Changer

8. Disposable latex gloves

9. Protective goggles

10. Syringe

11. Flat screwdriver

Role of the gearbox

The gearbox has several functions:

transmission of engine rotation to the wheels;

adapting the speed, power, and torque to the driving situation;

reversing the direction of rotation in reverse;

decoupling the motor from the wheels in neutral.

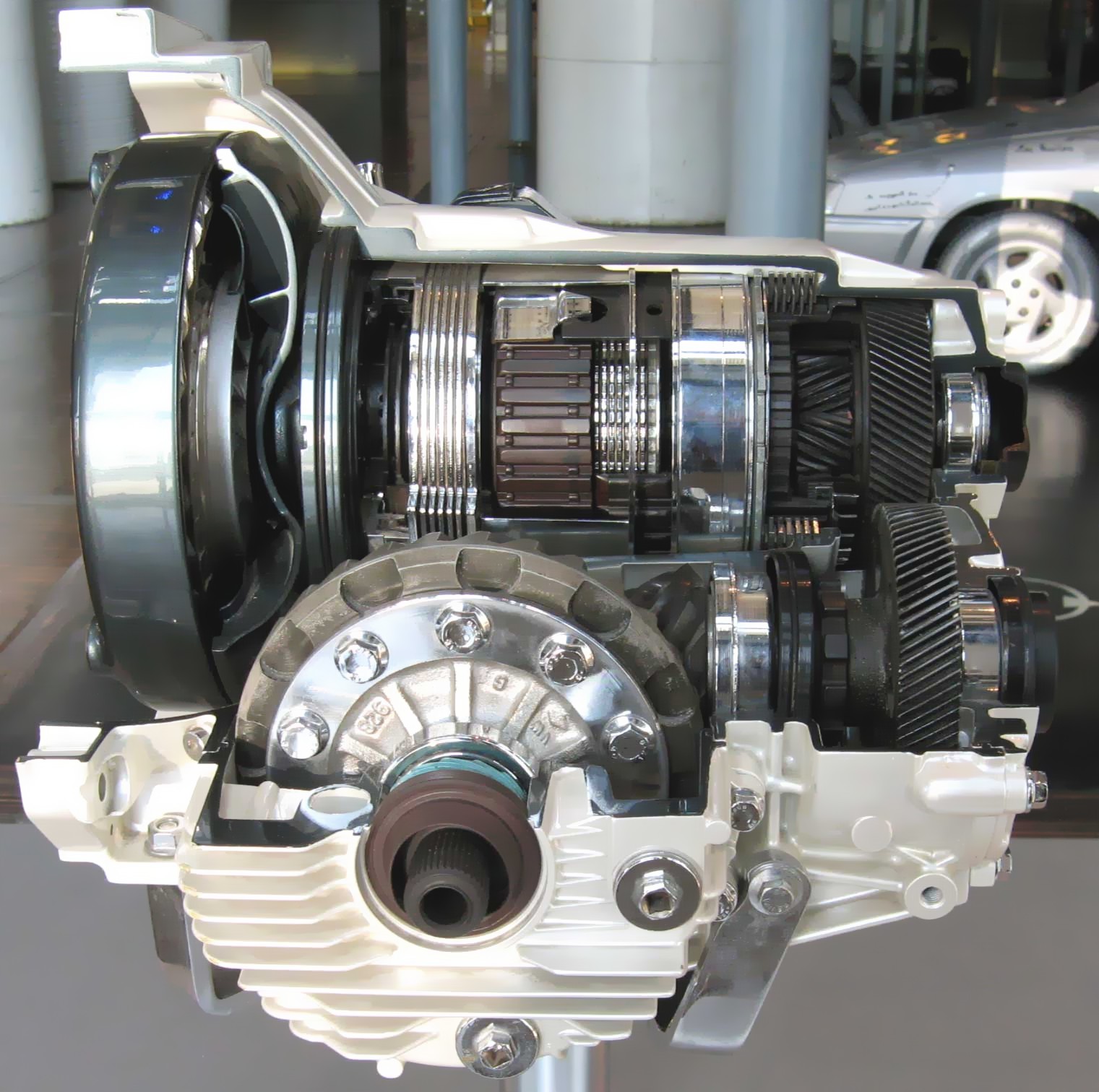

Operation of the gearbox with synchronizer rings

In the gearbox, depending on driving conditions, different gear ratios, defined by pinions of different diameters, can be selected.

The driveshaft on the motor side (primary shaft) and the shaft in connection with the wheels (secondary shaft) must have similar speeds of rotation before the movement is locked. This is known as “dog clutching”.

Mini clutches are available for this purpose in the form of mini clutches in the form of rings with a tapered seat, the so-called “synchronizer rings”. When the driver shifts gears, they gradually brake and tune the gears between the gears on the primary and secondary shafts.

Here are in detail these 2 situations to successfully repair a gearbox.

Gearbox problems

Case 1: Identify and repair an oil leak on the gearbox

An oil leak can cause irreparable damage if the oil level drops significantly.

Identify the problem

There are major oil leaks on the ground and in the gearbox.

In this case, the most common fault is a leak in one or both transmission spinnaker seals (or constant velocity joints).

Important: this repair, which can be carried out by a good DIY enthusiast, is nevertheless complex. It requires the removal of the transmission on the side concerned, which ensures the transmission of movement between the transaxle and the wheel.

Drain the gearbox

Place a drain pan under the gearbox.

Open the drain plug.

Drain the gearbox (as described in case 2 below).

Loosen the central gearbox nut.

Remove the wheel cover or centre cap.

Unscrew the transmission nut using a suitable sleeve.

Raise the relevant side

Loosen the wheel studs beforehand.

Lift the car with a jack.

Good to know: Make sure that the car is installed on a flat, horizontal and sturdy surface to provide good stability.

Secure it with a safety stand.

Remove the wheel.

Remove the transmission

Unscrew the lower suspension ball joint and remove it with a ball puller.

Do the same for the steering ball joint.

Remove the transmission by first disengaging it from the hub and then pulling it out of the gearbox.

Good to know: Sometimes it is necessary to remove an intermediate bearing attached to the engine block.

Replace the faulty seal and reassemble the parts.

Remove the gasket with a large screwdriver or tyre lever.

Important: Be careful not to damage the gearbox housing with your tool.

Clean the housing.

Before installing your new gasket, make sure that the part is in conformity.

Position the new gasket in its housing using a bush or tube of the appropriate diameter and press it in by tapping it regularly with a plastic hammer.

Important: Never insert the seal at an angle!

Lightly lubricate the lips of the seal.

Install the gear unit with the correct tightening torque.

Replace the drain plug.

Fill the gearbox with oil (see the following case).

Case 2: Replace the oil because the gears crack or are difficult to shift

Identify the problem

You notice a gear malfunction: one or more gears crack or are difficult to engage. This is often due to the timing rings no longer fulfilling their function. A lack of oil quantity or degraded oil can sometimes be the cause of the problem. In such cases, the oil must be changed.

Changing the gearbox

Place a drain pan under the gearbox.

Unscrew the drain plug and then, to speed up the process, unscrew the level and filling plug.

Collect the oil in the oil drain pan and allow the gearbox to drain well.

Inject new oil into the gearbox.

Start by checking the gearbox capacity in the technical review of the model.

Also, choose the right drain oil and a transmission additive.

Good to know: it’s this additive that can reduce or eliminate the creaking of the gears altogether.

Replace the drain plug.

Using a syringe, fill the mixture of oil and additive through the filler hole, which is often the level one.

When the quantity is correct, the excess oil escapes through the level hole.

Carry out a test

Check that the gearbox is working properly, without cracking.

If not, it is inevitable that the gearbox will have to be dismantled by a professional.